Powerforce announces plan to go dutch

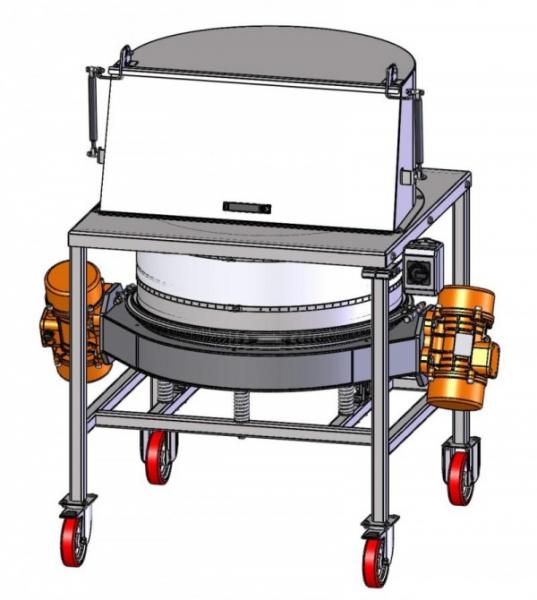

Instrumentation made in the Netherlands satisfies US requirements for precision, quality a Ever increasing cost of materials and growing stringent environmental regulations on food safety standards, consistent quality and track & traceability requirements, insist that the processing industry pays more attention to quality conformity.

The basic and most reliable measuring method to warrant all of the above is still defined by weight. Weight determination, from a chemical perspective essentially means counting molecules. Each type of molecule has its own intrinsic mass; therefore, it does not matter whether the product is a liquid, a solid mass, granules a powder or a gas, a kilogram will always be a kilogram irrespective of the substance.

By weighing a number of aggravating factors such as temperature (expansion/shrinking), compressibility, and changes in density and/or aeration are eliminated and have no effect or influence on preparing mixtures, filling packages or charging and discharging bulk material – the weight always reflects