Zhejiang Huakang Pharmaceutical Co., Ltd. in China focuses on RHEWUM WA Scr

After Roquette France and Roquette China, the world-renowned company Zhejiang Huakang Pharmaceutical Co., Ltd. now completely relies on RHEWUM sieving technologies, too. Here the company is taking particular care to the separation of sugar and sugar-like products.

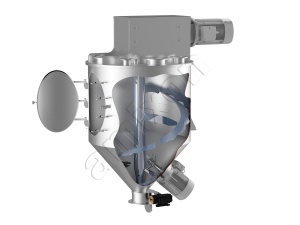

In the following weeks RHEWUM will deliver two screening machines type RHEWUM WA 150x269/3/V according to FDA standards (Food and Drug Administration) to China. The three-deckers will be used for separating sweeteners. Special features of the machines are the adjustable inclinations and the air drilling fluid circulations. Viewed over the long run, these unique designs of process-related components will guarantee efficient workflows. True to the RHEWUM-slogan — enjoy the difference.

Zhejiang Huakang Pharmaceutical Co., Ltd.:

Zhejiang Huakang Pharmaceutical Co., Ltd. is a worldwide leading functional polyols manufacturer, specializing in the production and selling of xylitol, maltitol, refined xylose