New VXD Series is smaller in size but delivers big advantage

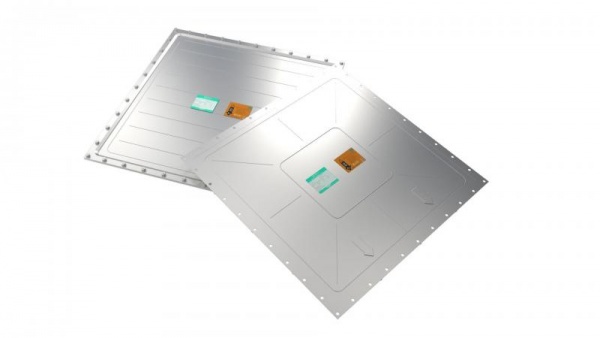

SMC has upgraded its market leading VXD Series, a pilot operated 2 port solenoid valve, so that it’s smaller in size and more energy efficient whilst still delivering big benefits to customers.

Ideal for air, water, oil, heated water and high temperature oil applications, ranging from car wash centres to oil lines in process industries, the renewed VXD Series is 7% smaller than the former conventional model, supporting SMC’s commitment to improving the performance and functionality of its products. As part of this focus to develop new innovations and drive energy savings for customers, the VXD Series now uses less power.

Available in a wide range of body materials – aluminium, resin, brass and stainless steel – the VXD Series offers low concentration ozone resistant and oil free options.

Labour time is also reduced, as the air version with resin body offers a built-in one-touch fitting option.

Other benefits to be derived from the refined VXD Series include