25 years NOLL: Silver Jubilee at POWTECH 2016!

Celebrating two and a half decades of smart engineering solutions for the refinement It all began in Bobingen in 1991 as »Ulf Noll Verfahrenstechnik«, a consulting bureau for dry powder processing technology. Today, NOLL is a highly reputed brand around the globe, from Brazil to Japan: »Finest processing places you first.« Many reasons to celebrate! Join us at POWTECH, the world-leading trade fair for processing, analysis and handling of powder and bulk solids which opens its gates at the Exhibition Centre in Nuremberg, Germany, April 19 - 21, 2016.

»Unique system solutions« by NOLL: our successful engineering concept far exceeds the standard procedures of fine particle technology. On the basis of our high-tech machine programme, every mill, every classifier is exclusively and individually configured to our clients and their specific applications. Unique and custom-designed to your product, »made in Germany«, truly energy-efficient, with minimal maintencance costs and easy to operate: multifunctional, stand-alone or combined.

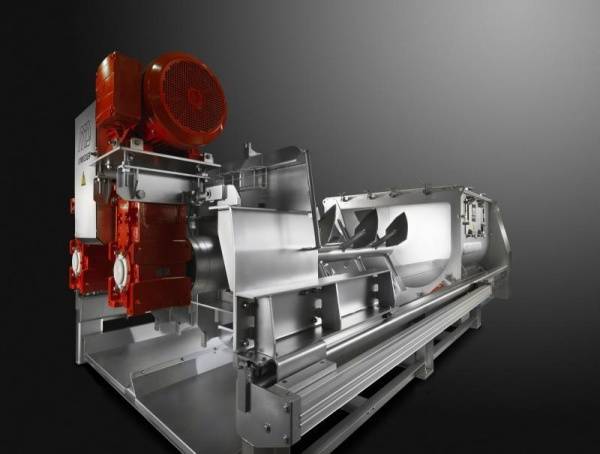

Impact jet