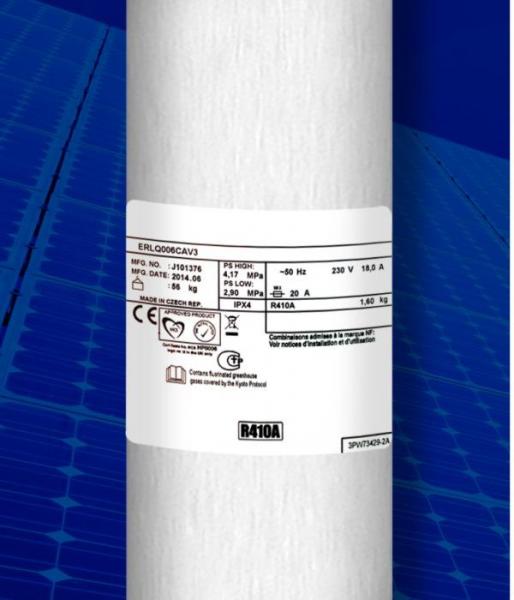

The toughest outdoor identification label

Resists UV-light, weathering, fluids and abrasion for more than 10 years Brady has developed a top quality identification label that resists UV-light, weathering, fluids and abrasion for more than 10 years. The toughest outdoor identification label in the market to date keeps equipment,vehicles, components and facilities clearly identified for more than a decade.

No overlaminate

Many outdoor identification solutions fade, shrink, crack or fall-off after a couple of years making them unreadable and therefore irrelevant. Brady’s new, halogen free and ultra durable outdoor identification label remains attached and clearly legible for more than 10 years in tough outdoors conditions. The label is uniquely weather resistant and doesn’t even need an overlaminate to protect its print.

Clear and durable identification increases the efficient use of equipment, components, vehicles, tools and facilities, and it doesn’t need frequent replacement.

Outside applications

Available in black print on a white surface, the toughest outdoor identification