Lightweight, flexible fall protection for those on the edge

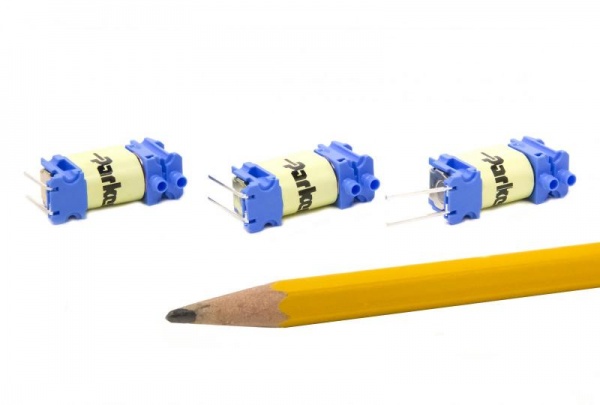

Honeywell has today launched Miller TurboLite TM Edge – a new lightweight and highly durable self-retracting lifeline (SRL), which, at just 1kg*, makes it the lightest 2metre Edge SRL on the market.. The new fall protection system, which is 15 percent lighter than most comparable products, offers users in the construction, maintenance, utilities and oil and gas sectors increased comfort, freedom of movement and immediate arrest in case of fall.

“We recognised a growing need for a lightweight, fully edge tested and compliant SRL, that would help workers in demanding conditions and environments feel safe and confident with their fall arrest device,” said Corentin Barbieux, product manager of fall protection solutions for Honeywell Safety Products, EMEA. “The lifeline has been designed to provide workers with a single solution for protection in all working at height situations, including those at foot level.”

Miller TurboLite Edge is fully edge-tested and