Fine powder bagging with Concetti

Fast and accurate dosing and filling of powders, including those that are extremely fine The Concetti Group is pleased to announce their participation at the Powtech exhibition, taking place in Nuremberg, Germany, from 19 to 21 April 2016, Hall 1 Stand 612.

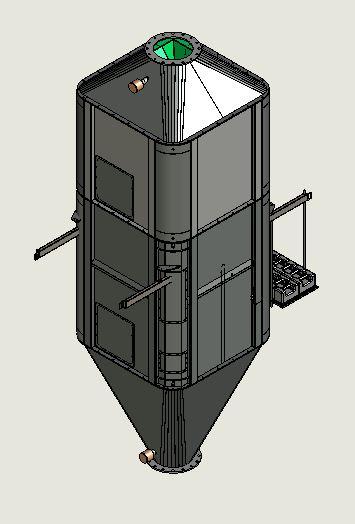

This year’s highlights include the successful IGF bagging machine range for various types of pre-made bags and the renowned Continua for FFS bags. Both models feature innovative devices allowing fast and accurate dosing and filling of powders, including those that are extremely fine, highly aerated and difficult to handle.

• Very light powders (below 0,1 kg/l), producing bags as long as 130 cm

• Fine powders, featuring many devices to guarantee product safety, a clean environment and producing compact, airtight and easy to palletise bags.

• Flour, with a MAP system for flushing inert nitrogen into the bags and so prolonging the product freshness and shelf life;.

• Cement, featuring six linear bagging stations for product de-aeration and bag compaction, designed to use standard PE tubular