Maximilian Hoyer new managing director of Lödige

Change at the top of Gebrüder Lödige Maschinenbau GmbH: Maximilian Hoyer is the new managing director of the Paderborn-based process technology specialist since July 2023.

Maximilian Hoyer has initially acted as commercial manager and authorized signatory at Lödige since August 2021. In his new position, he succeeds Dr. Frank Sandfort, who has managed the company on an interim basis for the past few months and is now chairing the advisory board of the family company again.

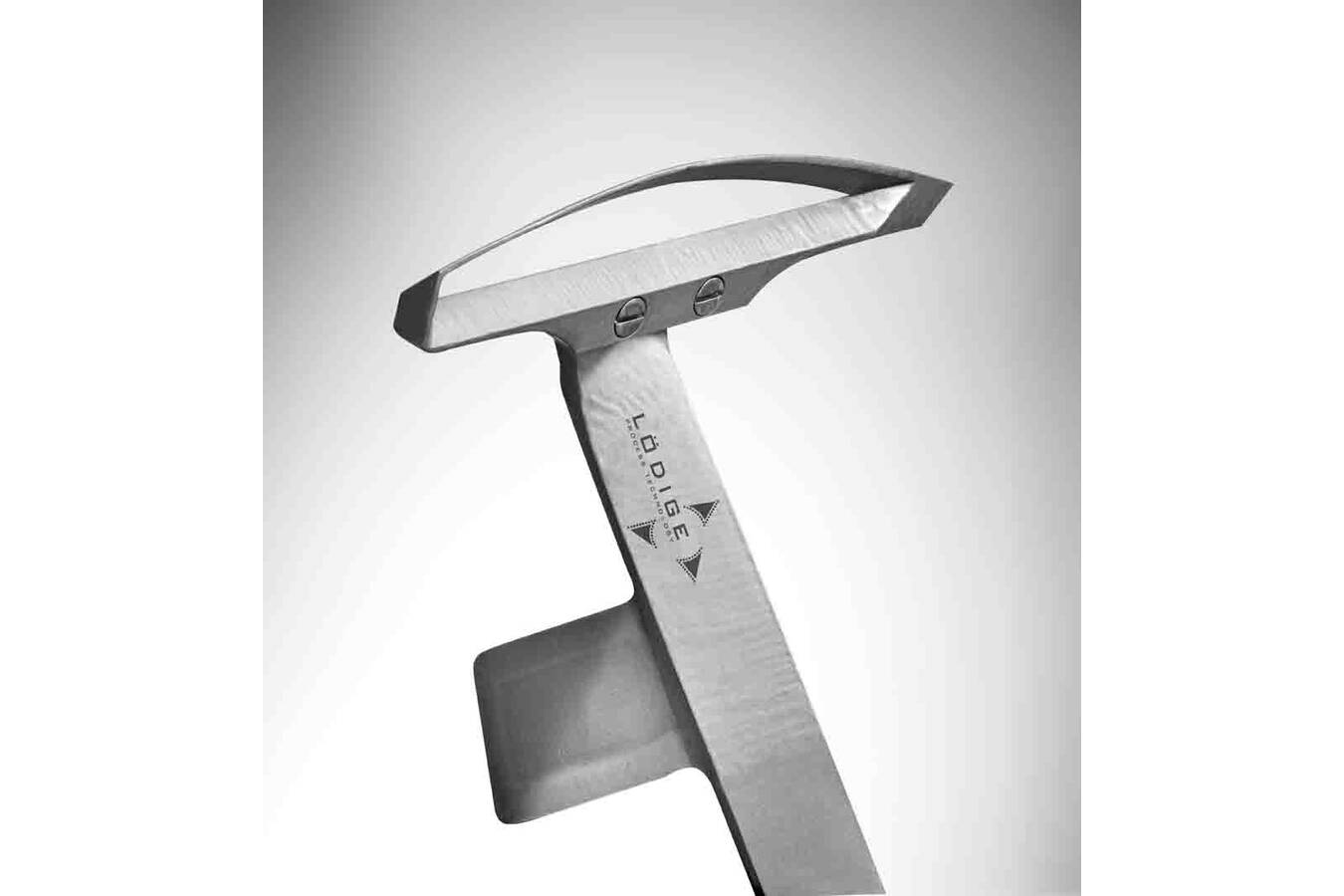

Founded in 1938, Lödige revolutionized mixing and processing technology with the invention of the Ploughshare® mixer, patented in 1949. In the meantime, the company is a leading global full-service provider for process engineering applications in the areas of mixing, granulating, coating, drying, reacting and related processes. The fields of use for the machines and systems ranges from the food industry to pharma, cosmetics, chemical products, plastics and many more.