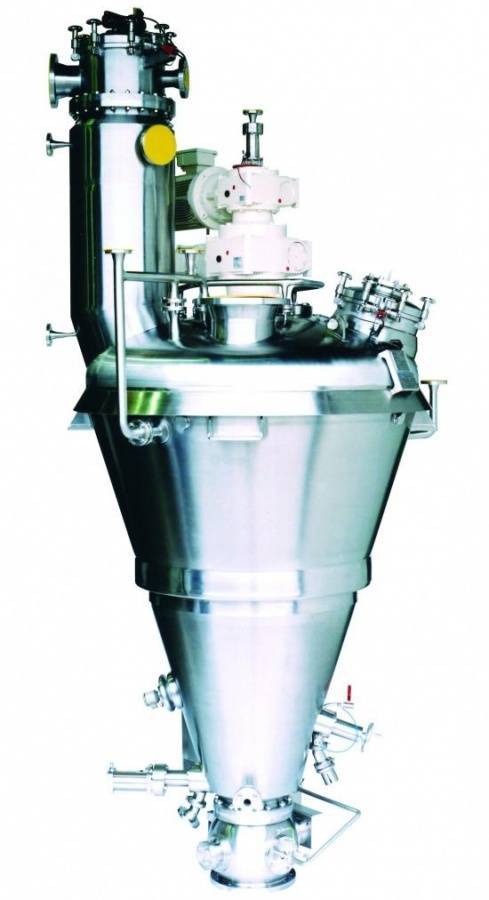

POWTECH 2017: The heart of mechanical processing technology

High number of registrations six months before event start Bulk solids experts, process technicians, engineers and plant operators from all over the world will gather in September for POWTECH in Nuremberg. On three days and in six exhibition halls, visitors will experience the latest equipment and systems for the whole gamut of mechanical processes from A to Z. Forums, guided tours and lectures complement the presentations by the around 900 exhibitors expected to attend. A new feature in 2017 will be the special display area Pharma Solids for concentrated pharmaceutical expertise in Hall 3A. POWTECH 2017 will take place from 26 to 28 September at Exhibition Centre Nuremberg.

Every 18 months, POWTECH brings together the global innovations in mechanical processing technology and for the analysis and handling of powder and bulk solids. Plant designers and operators from almost all segments, including chemicals and pharmaceuticals, foodstuffs, non-metallic minerals, recycling and ceramics, come together to update their knowledge