J-Tec builds production unit for LVT (Luxury Vinyl Tiles)

A French, leading producer of flooring solutions is one of J-Tec’s customers who fits perfectly into their niche PVC Processing. Recently, J-Tec built a completely new production unit for LVT. The complete scope consists of two compounding lines with storage silos, weighing systems, hot/cold mixers and automatic feeding of the downstream equipment.

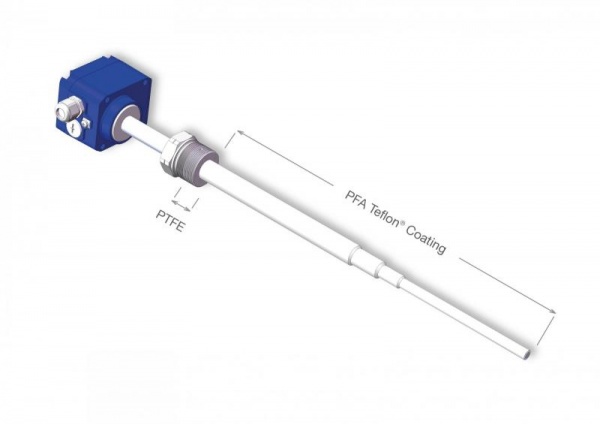

In total, J-Tec delivers ten silos, of which eight will store powder (PVC and filler) and two will store liquids (plasticizer). Because of its location in a valley with a strong “mistral”, the hoisting of the equipment into the 30m high tower was quite a challenge.

First, trucks fill the silos with raw material. Then, the material is pneumatically transported to the highest level (25m), in order to weigh and dose it (in batch). On the level below (17m) a hot & cold mixer blends the product. One level lower (12m), an LWF screw feeder receives the dry blend (PVC, plasticizer, filler) and doses it in an accurate