Continuous process in high quality:

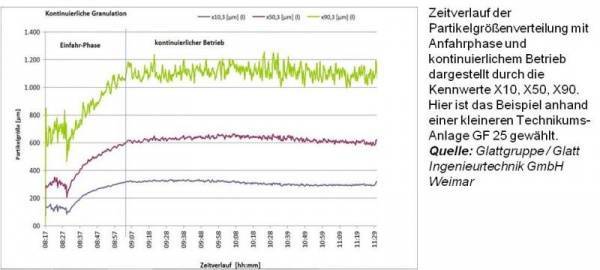

Inline particle measurement allows differentiated process control in the granulation To achieve a high quality production results, Permanent measurements and checks during the process are indispensable. Since sampling and evaluations are very aufwndig laboratory and provide only delayed opening information is precisely in these production areas inline measurement, with can be checked at any time and possibly affect the processes, particularly important. The IPC Process Center GmbH & Co. KG, a company of the Glatt Group, the innovative granules and pellets for producing the pharmaceutical and food industry, uses therefore for permanent monitoring of their sensitive processes inline particle probes of Parsum GmbH. With the accuracy of the probes IPP 70-S and IPP 70-Se the Korngrenverteilung the intermediate and end products is constantly under control, so that the processes can, accurately controlled. The optimal Prozessfhrung significant financial savings are possible. The installation of two inline-probes fr gives us the advantage that the production