New Cataloque Vortex Valves Quantum Series

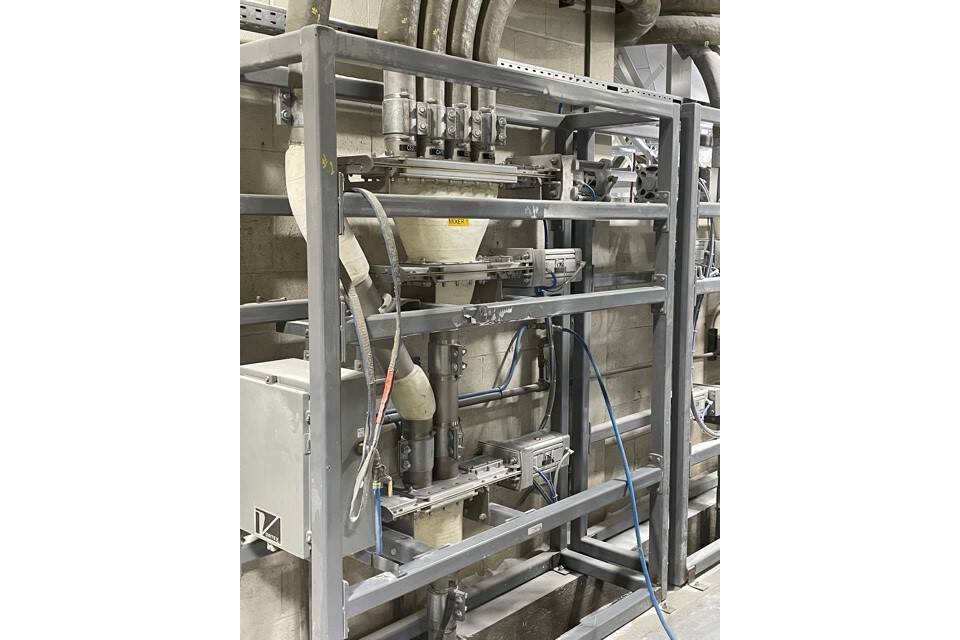

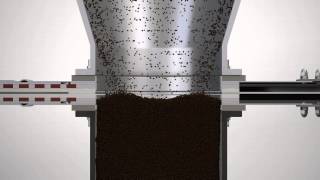

Ideal for handling dry bulk material in gravity flow or pneumatic conveying applications Vortex Quantum Series slide gates and diverters are the valves our customers have been using for decades to shut off, meter, and divert their dry bulk material. It’s our traditional line of valves for dry bulk processing and conveying through gravity flow or pneumatic (pressure or vacuum) conveying.

Some of the industries that use Quantum valves include but not limited to: Agriculture, Chemical, Coffee, Dairy, Foods, Milling, Pet Food, Petrochemical, Pharmaceutical, Plastics, Rubber, Textiles, Tobacco, and Wood – to name a few.