Sampling as a quality assurance tool

WEMO technique supplies a complete package of equipment and the know-how to obtain representative samples - automatically or otherwise - in order to guarantee the quality of production processes. Based on its decades of experience with worldwide projects in the feed, food and chemical industry, WEMO-techniek is in a position to recommend the optimum solution for every sampling challenge. Whether it is a fine powder or coarse grain, a raw material or end product, one or more positions; the systems of WEMO-techniek ensure representative samples. The programme varies from manual or air-operated sampling at one position to fully automated sampling at several positions, including transport, collection, packaging and labelling.

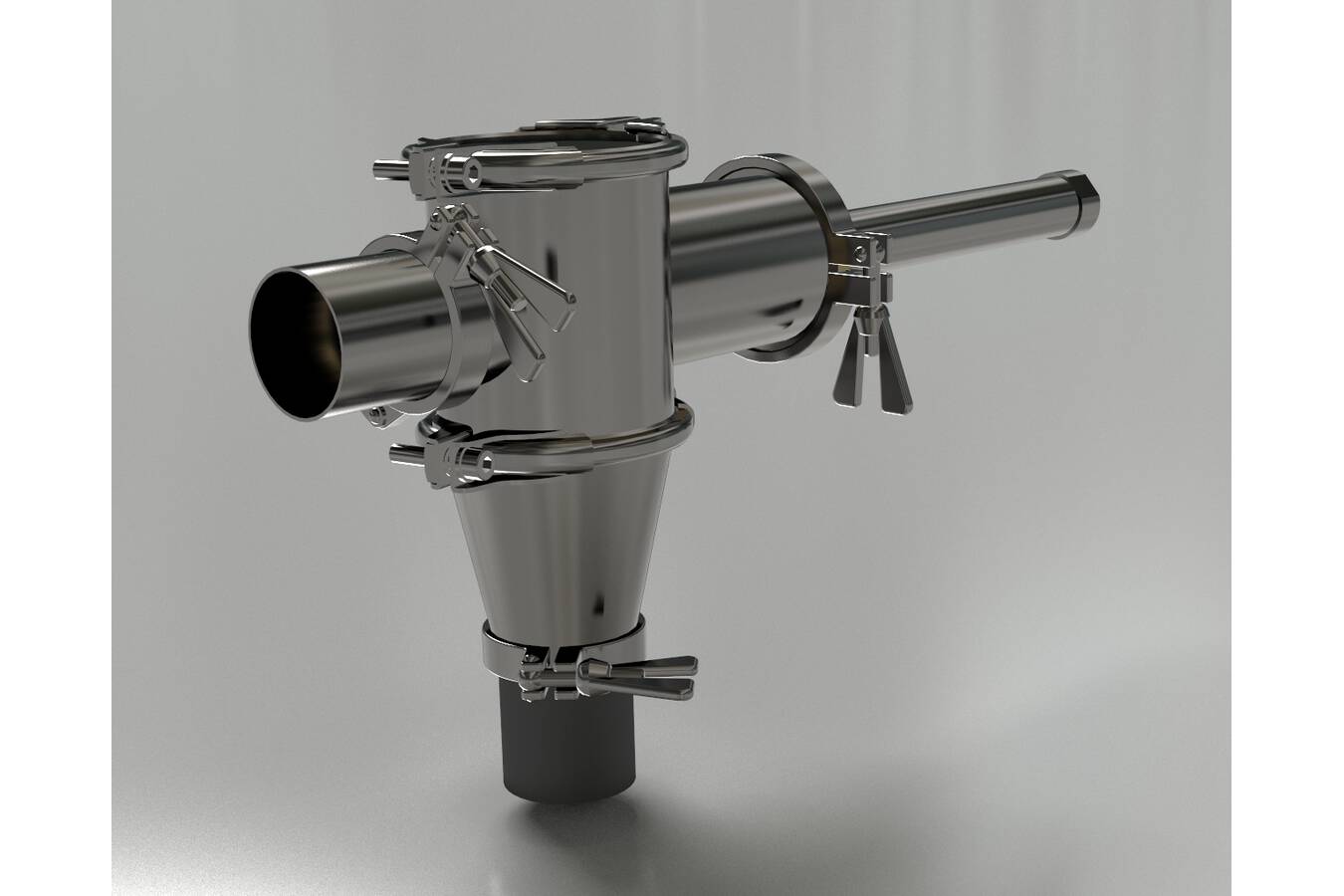

Sampler

With a range of standard samplers, most customers can be served directly. For a special application, it is possible to adapt a standard sampler or design a customised solution from a blank sheet.

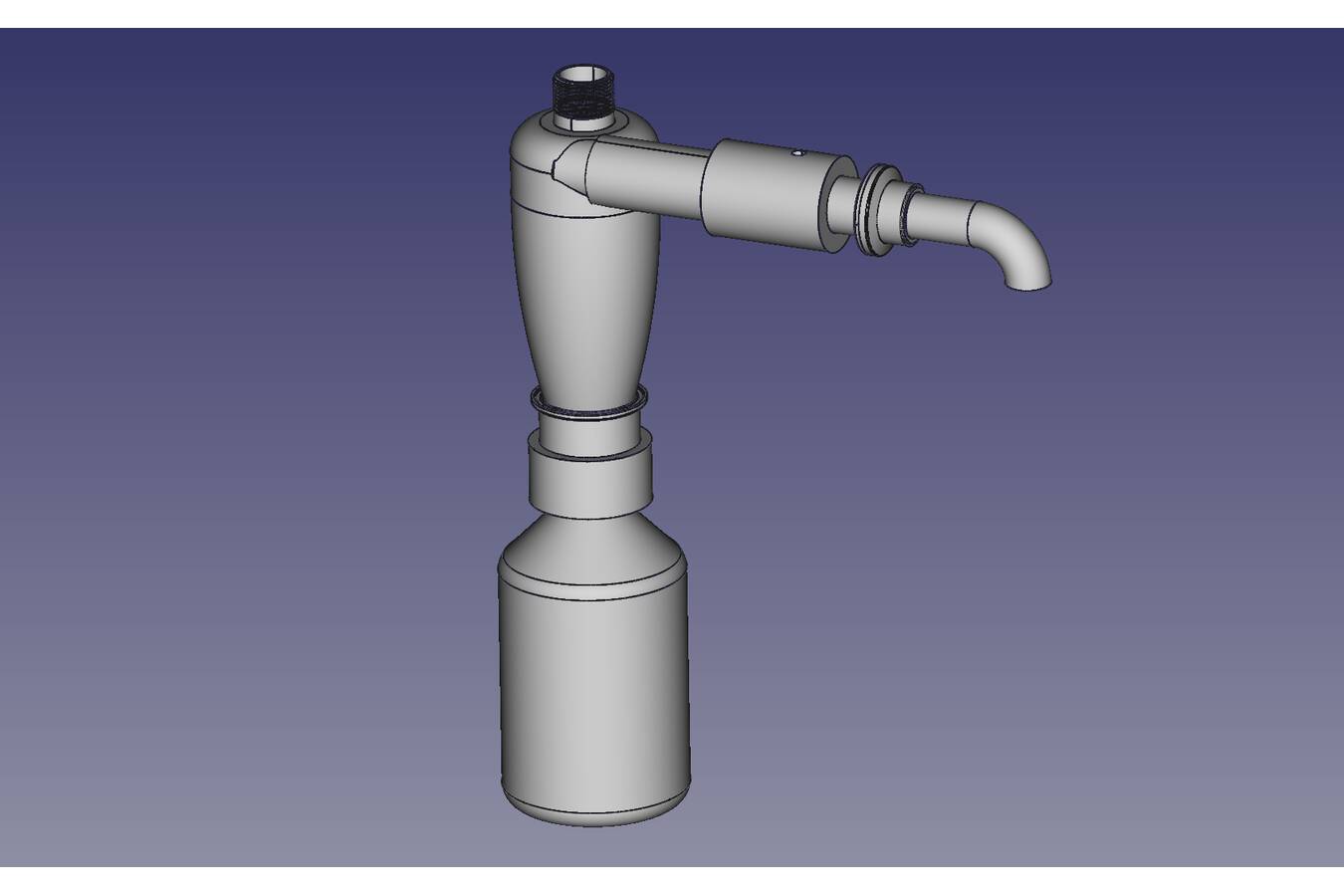

Automation

In easily accessible places, a sampler can be operated manually, whereby the material is collected via a hand slide in a bag or container, or in a screwed-on sample container. It is a small step to automate sampling from this