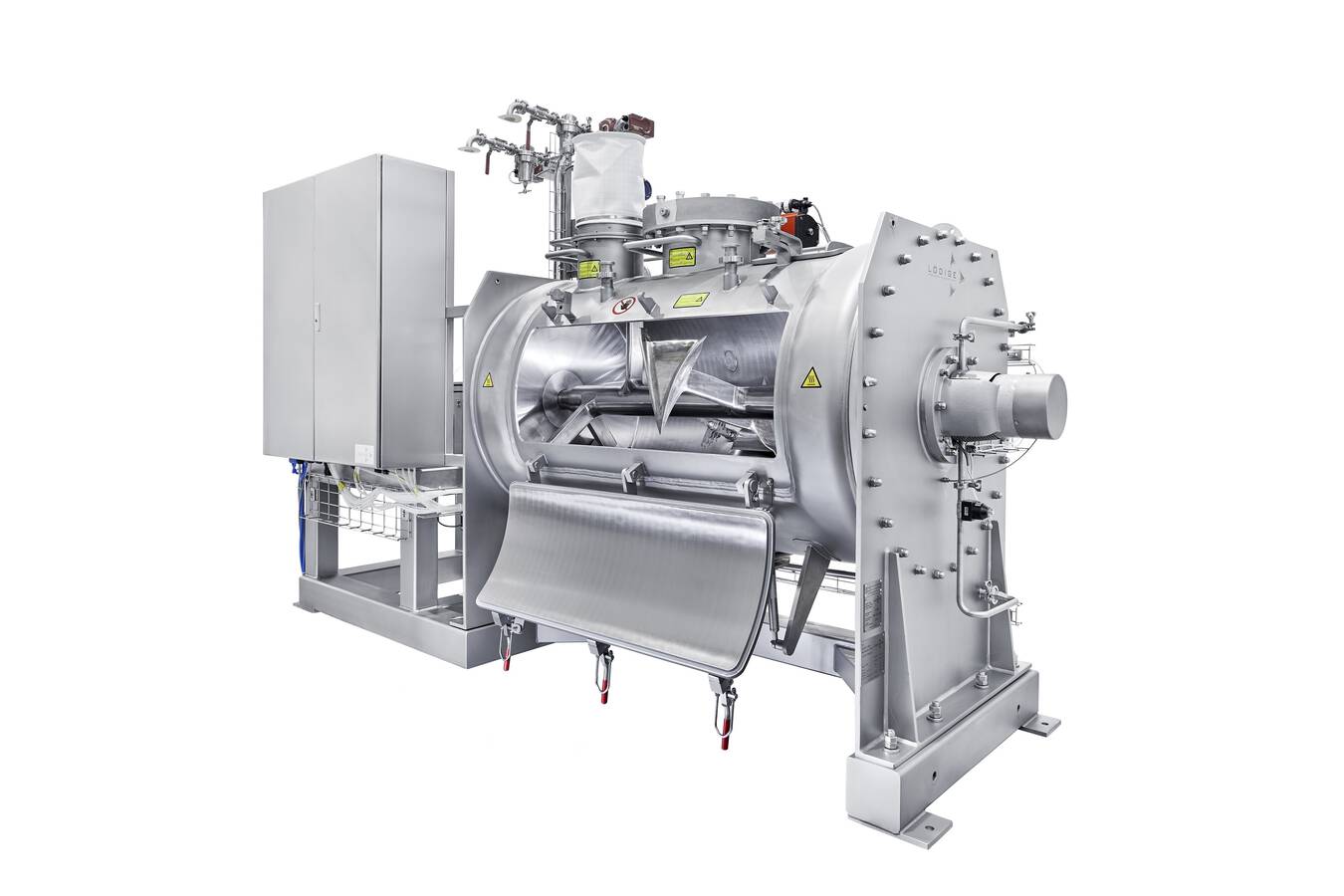

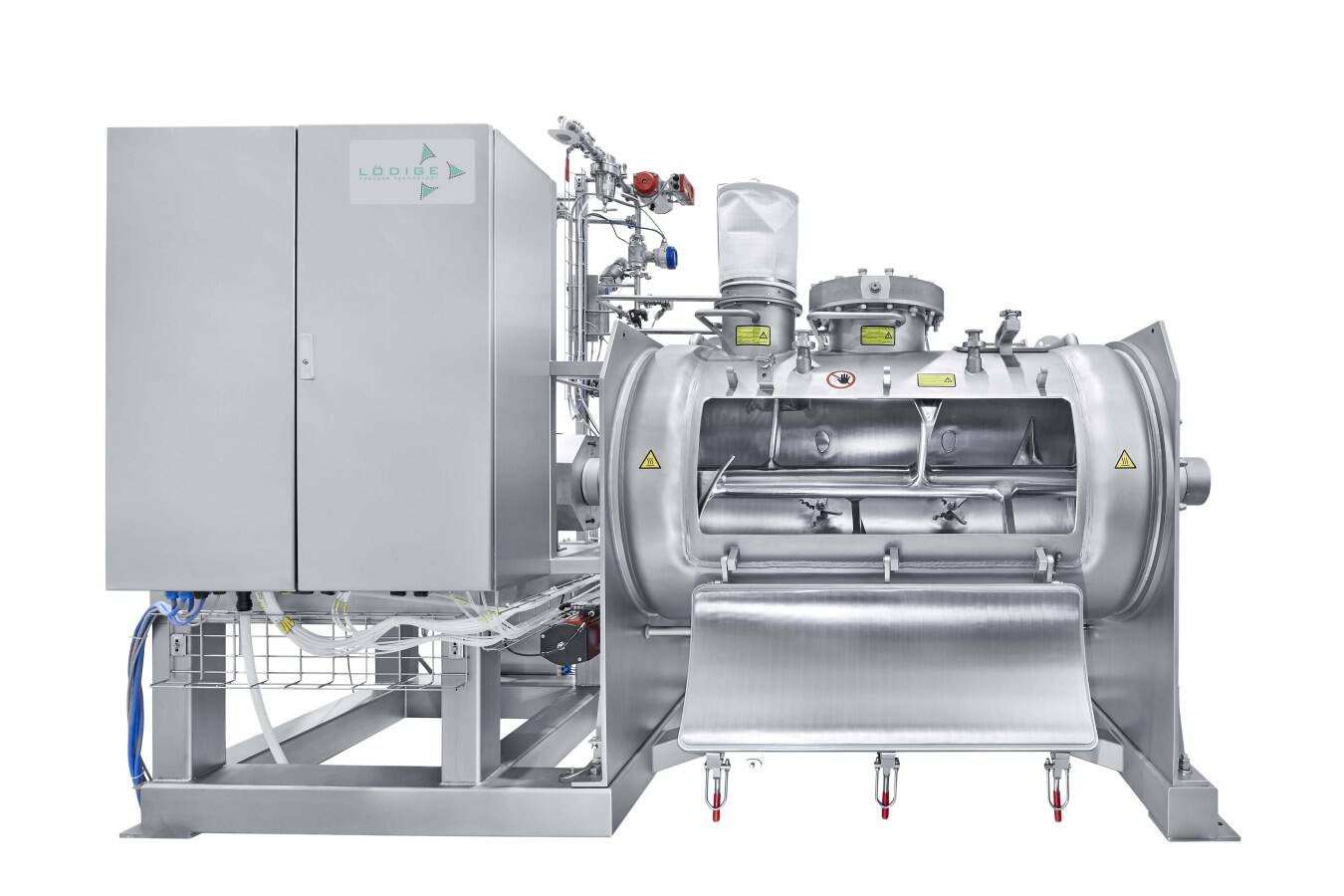

Production of veterinary chewable tablets in the Ploughshare Mixer

Efficient process technology for dogs and cats The demand for veterinary products is increasing worldwide – and with it the need for particularly efficient, hygienic manufacturing processes. As the example of chewable tablets for dogs and cats shows, Ploughshare® Mixers can meet the specific requirements particularly well in several respects.

From a technical process point of view, such chewable tablets mainly consist of dry raw materials: In the basic recipe, Active Pharmaceutical Ingredients (APIs) or other additives, such as vitamins or flavours, are added to a basic product (e.g. corn starch or protein powder). The first intermediate product is thus a powdery dry mixture. After this premixing, liquid components, e.g. liquid polymer (PEG or macrogol) or oils (e.g. soya oil, fish oil) are added and incorporated in a second step. At room temperature, however, these liquids can harden or crystallise in contact with the mixer or the mixed material before they are completely distributed. Therefore, both the