Aeration inserts - Siperm R, Siperm B, Siperm HP

Storage, mixing and discharge of bulk materials with average particle sizes of less than 0.1 mm frequently causes problems because these bulk materials do not flow freely and therefore are almost impossible to discharge. They tend to agglomerate and form bridges and tunnels, particularly around the silo outlet, thereby obstructing the free flow of the material out of the storage vessel.

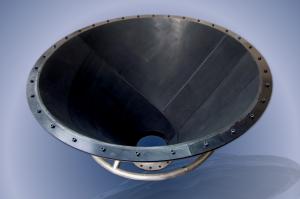

A proven solution to such problems is the fluidization of the bulk materials using custom-made aeration bottoms, cones or inserts which we manufacture to your specifications.

Dry, dust-free air is injected to reduce the friction and cohesive forces of the bulk material, producing a continuous flow of material out of the vessel. Air supply pressure and velocity of air must be set at such a rate that the contents of the silo are evenly loosened. When fitting-out large silo areas with aerations units, it is advantageous to divide them into sectors which can be aerated interchangeably.